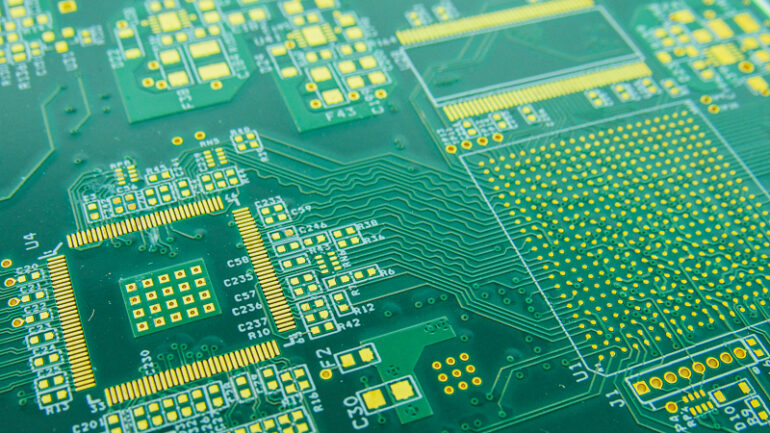

Consumer, aerospace, wearables, telecommunications, and automotive are just a few industries that use flexible PCB technology. Flexible Printed Circuit Boards have changed traditional electrical connectivity techniques, which were previously utilized to connect various sections of a circuit or different electronic devices.

In the current culture, Printed Circuit Boards are used in a variety of sectors and technologies. Our requirement for various types of PCBs grows as our technology advances. The possibilities when deciding between a single layer and a multilayer PCB can be confusing. Before you buy a new Printed Circuit Board, make sure you know the advantages and disadvantages of each option. Some of the advantages of purchasing a multilayer PCB are listed below.

What is Flexible PCB?

The flexible multilayer PCB is made up of many copper layers that are laminated and linked together before the components are soldered on the top and bottom sides. The inner layers are double-sided circuits stacked on top of one another to make a flexible Printed Circuit Board. Copper tracks, as well as pads/holes connect the electronic components electrically. PTH and blind are among the several varieties. As a result, a flexible multilayer circuit board with the most circuitry possible on a smaller circuit board is created.

Visit https://www.pcbasic.com/ to browse the best circuit board assembly company.

Benefits of Multilayer PCBs

Multilayer Printed Circuit Boards have various advantages in today’s technology. The following are some of the most important advantages:

1. Small Size

The modest size of multilayer circuit boards is one of the key advantages of using them. They are smaller than conventional PCBs because of their layered construction. Most modern electronics benefit from this since makers strive to create smaller, more compact gadgets. Multilayer PCBs are utilized in a variety of high-powered devices, including laptops, cellphones, tablets, and other devices.

2. Increased Flexibility

While not all multilayer Printed Circuit Board assemblies employ flexible manufacturing techniques, some do, resulting in a flexible multilayer Printed Circuit Board. For situations where modest bending and flexing occur on a semi-regular basis, this can be a highly desirable feature. This isn’t true for all multilayer PCBs, and the more layers a circuit board has, the less flexible it gets.

3. Light Weight

The smaller the size, the lighter the Printed Circuit Board. Multiple connections are necessary to interconnect distinct single and double-layered PCBs in the case of single-layered and double-layered PCBs. The multilayered design eliminates this, making it more compact. Because of its small size, it is ideal for current electronics that are more geared toward mobility.

4. Single Connection Point

Rather than being created in sequence with other PCB components, a multilayer Printed Circuit Board is designed as a single unit. As a result, instead of the various connection points necessary for using multiple single-layer PCBs, they just have one. This is especially advantageous in electronic product design, as the end product just needs to feature a single connection point. This is especially important for little electronics and gadgets that are designed to be as small and light as possible.

5. High Quality

From design to planning, multilayer PCBs are of excellent quality and durability. Single-sided and double-sided PCBs are inferior in quality. They’re also more trustworthy. Multilayer PCBs are also more durable than other types of circuit boards. They’re built to withstand high temperatures, high pressure, and their weight.

6. Cost Savings

The entire cost can be decreased with flexible Printed Circuit Board assembly. Errors and rework that frequently occur during cable wire assembly are minimized, and flexible PCB replacement is more convenient, thanks to the consistency of the wire specifications of the flexible circuit board and the application of overall termination. A flexible Printed Circuit Board simplifies structural design because it can be glued directly to the component, minimizing the clamp and anchoring elements. Flexible PCBs are less expensive when shielding wires.

Multilayer PCBs Have a Lot of Uses

Multilayer PCBs are preferred above other types of printed circuit boards by most of the industry. They’re employed in a variety of industries because they’re compact, lightweight, and efficient. Multilayer Printed Circuit Boards are used in the following applications:

Medical equipment

Electronics have become indispensable in the healthcare profession nowadays. From therapy to diagnosis, complicated machinery can be found in hospitals and other healthcare facilities.

Because of their lightweight, small size, and exceptional functioning, multilayer circuit boards are widely employed in the medical field. They’re found in a variety of devices, including heart monitors, x-ray machines, and medical testing devices.

Automotive

Automobiles now rely on technological devices to a greater extent than in the past. There are several electrical gadgets in modern cars, ranging from GPS to computers and headlight controls. As a result, when creating these goods, vehicle makers use PCBs.

Multilayer Printed Circuit Boards are preferred over standard PCBs because of their tiny size and lightweight. Multilayer PCBs are also long-lasting and heat-resistant, making them perfect for use in a car’s interior.

Aerospace

Rockets and jets, like automobiles, have a lot of electronics. Computers and other essential technology are available to them. Multilayer Printed Circuit Boards are the ideal answer since they are smaller, more resilient, and lighter.

Electronics for Industry

These are useful for manufacturing and industrial applications because of their modest size, versatility, and durability. They can withstand heat, pressure, stress, vibration, humidity, and other environmental variables encountered in a range of environments. Industrial robotics, automated assembly lines, automotive production, packing, and robots all use multilayer PCBs.

Military

These boards are a military favorite due to their durability, functionality, and lightweight. They’re especially beneficial in military-grade high-speed circuits. Flexible multilayer PCBs suit the military’s strict standards because they can endure difficult environments such as high-altitude, high-pressure, and high-temperature situations that could harm other components.

Conclusion

It does have its own set of advantages and disadvantages, yet when considering the pros and cons, the advantages of these units outweigh the disadvantages. Yes, multilayer boards are now widely and extensively employed in the majority of current gadgets. However, they aren’t appropriate for all types of gadget assembly. Multilayer circuit boards are at the top of demand in the current market due to an increase in the demand and supply of mobile devices, and it is certain that their value will rise over time. Multilayer printed circuit boards are the present and future of the electronics industry.