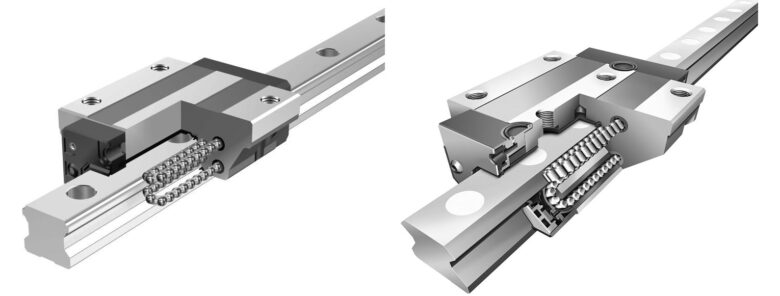

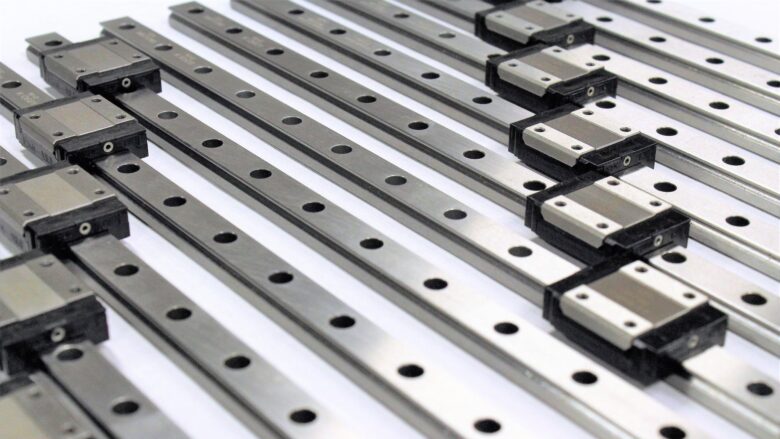

Linear rails represent a machine with two tracks that have rollers and balls on it. This machine is very useful in the industry, and there are various sizes and features available. The linear rails are necessary for manufactures, packing, and distributing goods. It represents a simple device that can make any process easier with the ability to move objects accurately. There are various types of linear rails, and you can visit Tuli if you need profiled rail systems, ball spines, ball screws and nuts, and more.

There are many benefits of using linear rails like the ones that you can get at TBI motion, and one of the most important is that you can easily manage some larger objects, even in the case that you need to move that heavy piece over a longer distance. This device is made of high-quality steel that is resistant to corrosion. There is a wide selection of sizes that can be of great purpose in the production line. Also, linear rails are a very popular solution for 3D printers.

When it comes to TBI motion, there is a great selection of rails and additional equipment available such as Economy Rails, Rail Guides, Linear Systems, Aluminum Rails, Clamping Brakes, and more. There are various types of applications that can be used during the process. Here are the most common applications for TBI motion linear rails.

Single Rail Applications

This machine has rollers or balls on both sides whose purpose is to carry objects, and it is capable of handling even those with bigger weight. The main reason why people choose a single rail is that it needs less space, and there is less risk for a poor adjustment of various components like ball transfer units, transmission systems, bearings, and other parts that you can find at TBI motion.

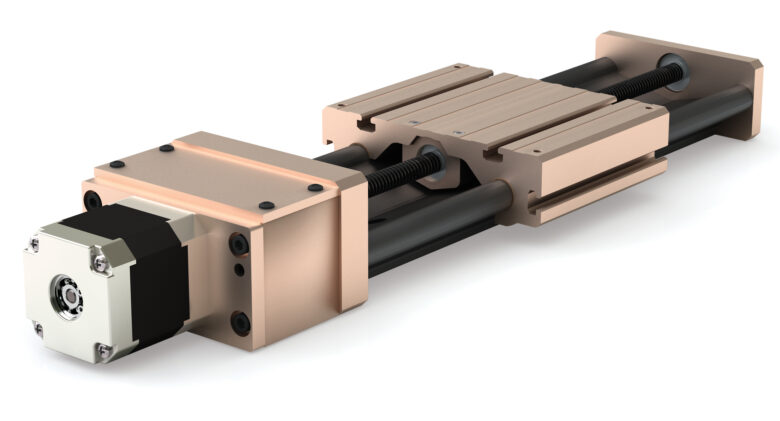

Applications that use single linear rail are linear actuators, overhead transportation systems, and gantry robots. Linear actuators are using pneumatic cylinders, belts, and screws, and their main benefit is high resistance to weight. Also, it is perfect for systems with belts since the actuator is capable of working in faster processes. Also, it connects a linear rail with bearing blocks.

On the other side, transportation often requires an overhead system that is capable of carrying heavy objects, and a single linear rail is the best option since it offers better stability. Gantry robots are useful for packaging, and they are using a single rail system with a three-axis system for improved accuracy and speed.

Dual Rail Applications

In case that a process in production requires a more complex system, you can combine several single linear rails to improve the capabilities. You will need additional devices for such a system, like Av roller rails, covers for linear slides, flanged roller rails and blocks, and other TBI motion equipment. There are several types of dual applications, such as linear stages, machine tools, Cartesian robots, and transport units.

Linear stages are necessary for systems that require high accuracy. These rails are used for devices that have to reach a distance over their bearings and slides. Therefore, dual applications offer a wider choice for manufactures and other industries. Moreover, a single rail is not capable of dealing with systems that are producing high-quality components. When it comes to Cartesian robots, dual-rail provide it with wide use in production, better function, stability, and precision. The est example for use of a robot transport unit is a coal mine, where you need a machine capable of carrying a few tons of material. The dual rail system can transport the robot from one place to another, providing it with a wider range that can be over 20 meters.

Main Advantages of Linear Rails

One of the most important features is the capability to deal with heavier loads and carry them in different directions. Warehouses and production lines have the great advantage of using rail systems because it has a positive effect on their efficiency. Also, this machine can work very fast and provide you with maximum accuracy, which is especially important during the production of components. Nonetheless, when we compare it with other systems, linear rail is much easier for proper maintenance, and the process of installation is not complicated. Also, stores like TBI motion offers you all the necessary parts in one place.

The Bottom Line

When it comes to TBI motion, there is a variety of balls and screws that you can use in every system. Also, there is a TBI motion angular ball spline, with 40 degrees angle, which is perfect for processes that require higher sensitivity or carry heavy loads. Products from TBI motion can be used in the robot industry, machinery, machine tool production, automation industry, medical equipment production, and automated warehouses. On the other hand, there are also some potential issues with this system. Materials could affect the machine, and you should always know the limits of it, especially for some heavier objects, since preloading could lead to malfunction. Also, always perform a test before you start using it to avoid additional expenses of maintenance. Moreover, check that all parts are functioning well and be aware that some of them need to be changed more often.

The crucial part of maintenance is the proper lubrication of the rails. In most cases, you will get an already lubricated system. However, always take care that the level of it is enough to finish any process. The lack of lubrication can lead to bigger problems. The best way to notice if there is a potential problem with lubrication is when the machine starts making unusual noises. TBI motion offers a wide selection of parts for linear rail systems that have a lubrication system. When you are aware of all factors related to proper maintenance, you should not have any issues with the system. The main use of linear rails can be found in CNC machines, 3D printers, heavy-duty machines, and much more.