In recent years, laser welding technology has advanced by leaps and bounds, becoming an integral part of various industries. One of the most exciting applications of laser welding is in the manufacturing of batteries.

Battery laser welding offers precise, clean, and efficient joining of battery components. In this guide, we will delve into the science behind battery laser welding, explaining how it works and its significance in the year 2024.

Understanding Laser Welding

Before delving into battery laser welding, let’s first understand the basics. Laser welding is a technique that uses a high-energy beam to melt and fuse two or more materials together. It is widely used in manufacturing due to its ability to create strong and precise bonds with minimal heat-affected zones.

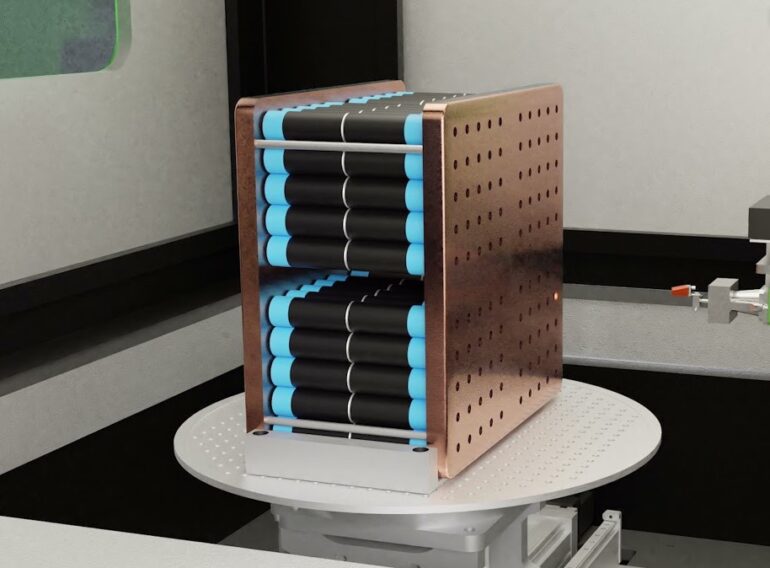

The Components of a Battery

To comprehend battery laser welding, it’s essential to grasp the components of a typical battery. Batteries consist of multiple layers, including the cathode, anode, separator, and electrolyte. These layers must be joined securely to ensure the battery’s structural integrity and performance.

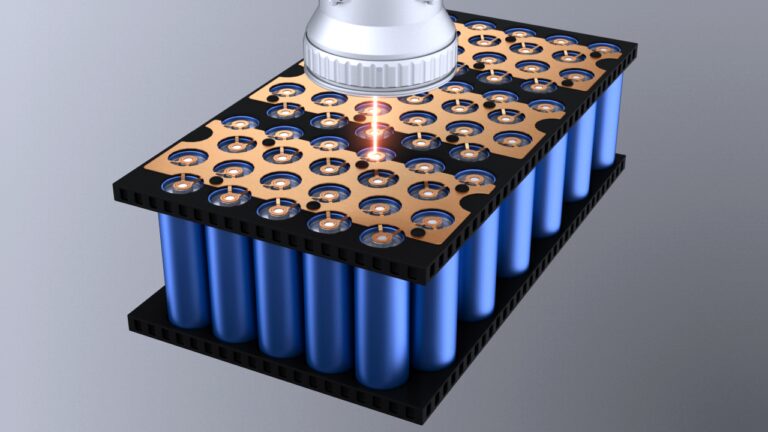

The Battery Laser Welding Process

The process of joining the different parts of a power source together with a focussed laser beam is known as battery laser welding. This is how the procedure goes:

Preparation

Before the process starts, the components are meticulously prepared. The surfaces to be welded are cleaned and aligned precisely.

Laser Beam Focusing

A high-power beam is focused on the area where the cutting is to occur. It generates an intense heat source, raising the temperature of the material rapidly.

Material Melting

The heat energy causes the materials to melt at the welding point. The high precision ensures that only a small, localized area is affected, minimizing heat dispersion.

Solidification

As it moves or is turned off, the melted material rapidly solidifies, creating a strong bond between the components.

Quality Control

Post-welding, quality control measures are implemented to ensure that the welds meet the required standards. This may include non-destructive testing methods such as visual inspections and ultrasonic testing.

Advantages of Battery Laser Welding in 2024

In 2024, the manufacture of batteries will benefit greatly from cell laser welding due to its many benefits, including:

- Precision ─ Precision control over the process is made possible by beam welding, producing welds that are reliable and of high quality.

- Speed ─ The rapid heating and cooling of the laser make it a fast method, contributing to increased production efficiency.

- Cleanliness ─ A clean and contaminant-free environment is guaranteed by the minimum spatter and fumes produced by laser welding.

- Reduced heat-affected zones ─ The localized heating minimizes the heat-affected zones, preserving the structural integrity of components.

- Environmentally friendly ─ Due to its reduced waste production and energy usage compared to conventional techniques, laser welding is a sustainable solution.

Conclusion

In conclusion, battery laser welding is a cutting-edge technology with a significant impact on manufacturing in 2024. Its precision, speed, and cleanliness make it an essential tool for producing high-performance batteries. As technology continues to advance, we can expect further innovations in techniques, further enhancing its role in the manufacturing industry.